Posts tagged 'production':

Pulling base card sets

We have setup stacks of all the base cards (162). Task is to pull one of each to collate a base set. Rinse. Repeat.

We’re trying different methods to collate base sets. First method was to take a handful of one card, then deal out one into each box bin. Then pick up a stack of the next card, and deal that one out. Repeat 162 times. This second method, walk around pulling one of each, seems to be faster, which surprised me.

collating base card sets

Suckpax 1 sheet cutting

Found some pictures of slicing the sheets up into individual cards.

There are 50 cards to a sheet, and first task is to slice the sheets into strips, then into individual cards. I had a row of card boxes prepared to receive cut cards. A sample of each card was taped to the end of the box. This is very handy for managing the cards later, not having to open every box to find a certain card.

cutting up sheets

The first edge has been sliced off of these sheets.

Strips of cards

Wrapper printing for Suckpax 1

In the same week of card printing, we printed the pack wrappers. Great artwork from The Sucklord again, a vivid design with strong dynamic graphics. I had many meetings with the printer to establish a process to emulate the old 80’s wax wrapper look and feel using modern materials. Much more difficult than one would think. Recreating the old low quality printing and paper is hard today. The industry has moved far in improving resolutions, glossy stock paper, inks, and printing plates. Telling a printer that you want 80’s quality is like going to a current video game maker and saying you want them to design in 8 bit graphics so that it looks like Mario Bros. They hear the words you are saying, but are baffled by what you are telling them.

Anyway, I convince them to give it a try.

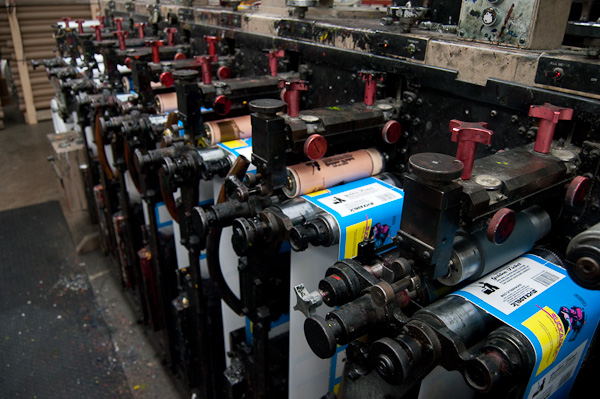

Paper comes off a roll like toilet paper, and is fed through sequential rollers. Each is a different color/plate, like wood block printing.

Wrappers are flowing

A cutter at the end slices out individual wrappers, which are stacked and packed.

Suckpax 1 cutting

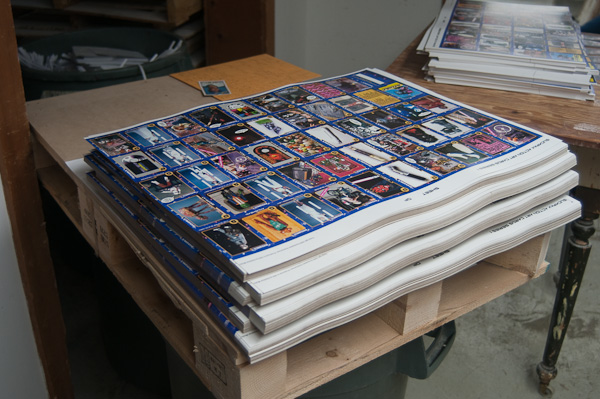

Fully printed sheets came off the printer in stacks.

Once the sheets were printed, they had to be sliced and diced into individual cards. Another reason I chose this printer is for their old hand operated cutter. Vintage cards were often slightly off in their centering, and that would happen automatically with hand registered slicing. These boxes were set to collate the finished cards, and are sitting on the cutter.

Suckpax 1 Card printing

I’m going back in time to create a series of posts detailing the Suckpax 1 production. Now that all the boxes are sold, the tale can be told. Secrets can be revealed and banalities tucked into hiding.

July 2009

First came the cards…. The Sucklord created a phenomenal set of cards. All the photoshop files came to SideKick and we marched off to our printer.

To produce the look and feel of the 80’s era cards, I searched for a print shop that still ran a vintage printer. Bunch of looking, and I found a small company in Vermont with this machine in their basement.

The raw chip back paper stock was something unfamiliar to the printer, and it was a struggle to get the job to run correctly without shredding sheets or printer parts (one set of blankets was lost).

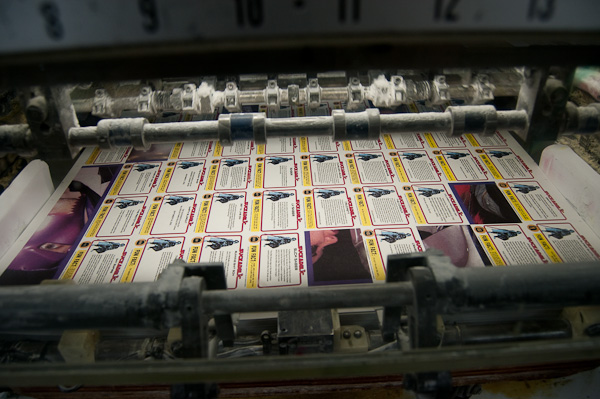

The printer is checking first sheets.

Everything dialed in, printing running smoothly. The sharp eyed will notice that this sheet is showing the back side, and is printed on white stock instead of chip back. This was done to create the sketch card blanks. These cards had to be on white/white stock, so about 150 sheets were printed on white/white paper. Then we cut out just the one card position, and discarded the rest of the sheet. It seems wasteful, but far cheaper to print an extra 150 sheets than to make up a set of 4-color printing plates for just one card repeated 50 times and then print just 3 sheets. Saves paper, but the cleanup of the machine between plates is more wasteful. Once we had the white/white sheet stock printed, the rest of the run on white/chip paper stock was completed.

Recent Comments