The Art Hustle box building

Boxes were printed, and I then drove the stack of printed sheets to our Die cutter. This was my first time designing a die-cut pattern, and it worked out great. I made the die cutter nervous, because I ran the total job out of order. Normally, the die-cut pattern is made first, a die created, and it is tested with blank sheets. A low pressure sheet is done, so that it has creases instead of cuts. This creased sheet is then sent along with artwork to the printer, who uses both to position the artwork within the rectangular finished sheets. I did this out of sequence, in that the artwork was printed onto stock sheets, and the die-cut created independently. We skipped the test run, and positioning stage. All bets were off if it would come together. I was confident it would work, and in the end, it was fine.

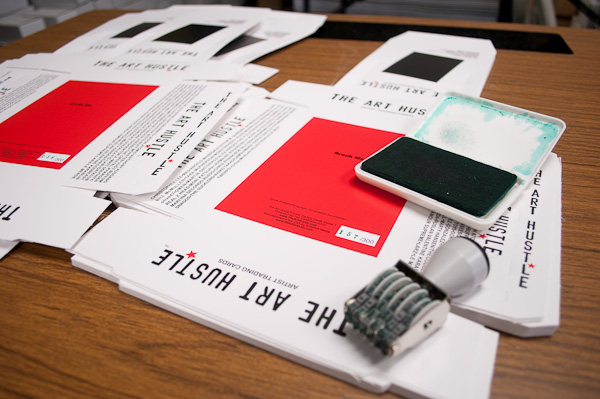

Back at the Lab, we number stamp each box. Promo boxes are numbered also, but are also labeled PROMO in green near the number.

Actual cards are glued to the tops of the boxes, one of the above 15. There are 20 boxes for each card.

Finally, we fold and glue the four corners of each box.

10 packs of glued, flattened boxes.

Recent Comments