Posts tagged 'production':

Countdown to NYCC, D-29 ramping up

This week is going to be a lot of late hours, a lot of time devoted to getting stuff ready to send out for fabrication.

Biggest things (highest priority):

Artwork for Cards. Deadline to get final artwork to printer is Friday (Monday if I have to). I have 83 in hand (out of 110). The Sucklord is working on about 12 more. Simeon has asked for 6 slots, but not sent art yet. Datadub is sending in art for one card. This leaves about 9 open slots for cards.

Ride-alongs! I have a bunch of SideKick related cards I can add in, if the slots stay open. I have sent out an appeal to my cronies to see if anyone has cards they want to include.

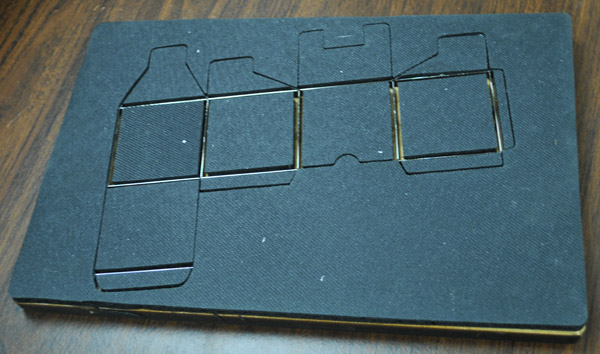

Die-cutting fixtures. I have to send out to have special fixtures created for Die-cutting stickers.

This is an example for a small box. I do the design in Illustrator, send to fab company, and it takes about a week to have it made.

Letter to Artists: Any artist who has worked with any project associated with SideKick is invited to make a guest appearance at our NYCC booth. I need to write this up as an email to send out.

R&D: Still working out some technical aspects of special cards to go into Suckpax 3. Got some cool new things to slip into packs.

Suckpax 3, Sticker cards, test layup

The Sucklord designed a kick-ass set of stickers for the set. 9 different, and we are going to kiss-cut them like vintage sticker cards (Garbage Pail Kids, Star Wars, etc). I had a company make up a custom batch of sticker material, which matches the composition and thicknesses of the old style stickers.

Just printed a test layup of the 9, and some of the cards may need some size adjustment.

Once the artwork is locked down, I can design the steel rule die that will do the kiss-cut.

Digression: Kiss-cut is not what tough girls do, but when a pattern is sliced into the top layer of a multi-layer material. A die is carefully shimmed so that it only cuts through one layer and not all the way through the stack of material. This yields a sticker where you can peel away just part of the front, shaped in some way.

I am excited thinking about some of these stickers showing up on lunch boxes.

Suckpax 3, pack wrappers, prototype

The Sucklord finished the excellent artwork for Suckpax 3 wax wrappers. Continuing the permutation of the Suckpax CMY color scheme, the primary color is Magenta this time.

These are a couple of test prints (inkjet) which we waxed and wrapped to see how the wrapper fits.

Looks OK to send out to print.

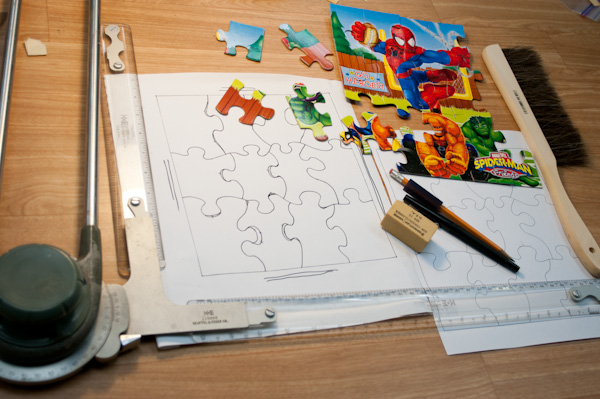

Suckpax 3, special cards, puzzle, die cut design

Did a design/layout for a 12 piece puzzle. Each piece had to fit into a wax pack, so had to fit within a 2.5″ x 3.5″ rectangle. Fun to lay it out. I picked up an example at the local dollar store, to see shapes. After the sketch, I inked and scanned. In illustrator I then created paths for the outlines. The illustrator file will go to the die cut maker. I made the design generic, so I can recycle the die for other future card sets. Could make for some weird puzzles, when you can use pieces from different card series and fit them together.

Some of the piece outlines got a little looser, and more trippy, as I progressed. Wondering if I should redo the early ones to match the swim-ey style.

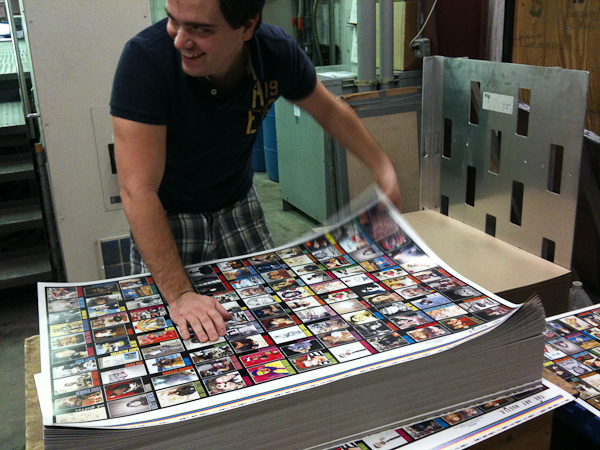

Print run for The Art Hustle series 2 cards

Simeon from CardHacks was up from New York, to do a press check for the card printing.

Examining the first sheet off the press.

Pressman checking the color and registration.

Printed on front side only, the pressman now preps the sheets for printing the reverse side. Corners are curled, and the entire stack is flipped over.

First sheet of back printing, last check before hitting the go button.

Finished sheets are now cut into individual cards. about 200 sheets cut at a time, and each final card stack is called a “lift”. The shop took great care of us, mounting a fresh new blade on the cutter just for our run.

Lifts are packed into cartons for shipping to the SideKick Lab.

Simeon is pleased with the finished cards.

Recent Comments