Archive for October, 2010

Sheets of Suckpax 2 cards hot off the press

Had a great day at the printers yesterday! A great team, relaxed and expert. Several pressmen and managers came around to check the progress, and meet and greet. Some of the cards are a bit raunchy, and the whole job is very different from their typical work. I think a few came around to see who had brought in such odd stuff.

I was excited about the printing, and they put up with me running around with my camera. Above are the stack with fronts only printed. These are about to be flipped over for backs to be printed next. They have a huge clamp that grabs the whole stack, then pivots 180 degrees and puts them back down. I arrived at 11am for “press check”, which is to observe the first sheet printed for quality. The fronts were right on the money.

Punching the printing plate for mounting in the press.

The most important issue for press check was the backs. The Sucklord has put secret messages on the backs, and the color balance is critical to have the whole decoder system work properly. We had done multiple experiments pre-press on the same material, to get the art as close as possible. I had expected to need some adjustments at the press (raise or reduce opacity of ink) to get it right, but to my happy suprise it was exactly correct the first sheet, no need for changes.

The sheets have to sit and dry for a day, and will be cut up into individual cards Friday morning. I will be picking them up in the afternoon. On the same trip I will be picking up some materials for special inserts.

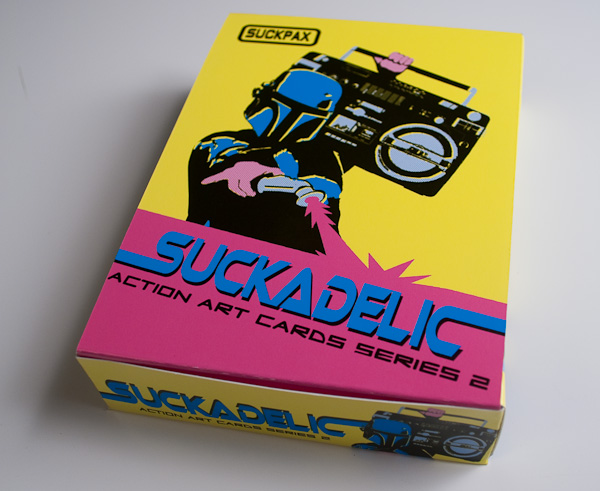

Suckpax 2 proofs

Went to the printer today, to review the proofs for Suckpax series 2. Some adjustments required, all for my own cards. All art files provided by The Sucklord flew through perfectly, without any need for changes. Went over printing plans, they are scheduled to flow through the press next Wednesday. I will pick them up Friday (yeah!). I blurred out some faces not ready to be seen. In the closest row you can see some of my prototypes for a series on Tractors, which I fit into empty slots.

Suckpax 2 assembly

(above is the prototype box)

We begin Assembly Nov 1st, with first day of sale Nov 5th.

Status as of today:

Cards – artwork delivered to the printer. I go visit them to view proofs onsite Friday 10am.

Boxes – Blanks are printed, and the die-cutter will be punching them early next week.

Wrappers – Artwork is at the printer, should be run by middle of next week.

Hot foil dies – Artwork sent today, die maker will ship back to me next Tuesday.

Special inserts – My current focus, lots of little details and aspects to still nail down. Part research, part design, then ordering.

Lots of little details, like I just remembered I need to order a rebuild kit for the shrink wrap cutter.

I am hoping cards will arrive on or before Oct 30th. There is 2 days of labor to go get them from the printer, and to unpack and collate into handling bins. Which reminds me, I need to build more handling bins.

Suckpax 2 trading card artwork delivered to the printer

At last, all the artwork for 110 trading cards have been sent to the printer for pre-press. It has been a hectic few days, a lot of emails and phone calls flying around. Now we can take a break to catch our breath, and the printer can get busy. We expect finished cards by the end of the month, and assembly to start on Nov 1st.

I had space on the layup to fill in a few prototype cards, for 3 new series I am developing. It was a last minute scramble to finish them. I learned I need to have a batch of ready to go prototypes (all electronic artwork finished) on the shelf. As a series goes to press, it is only at the final stage I learn how many open card positions exist. In this series, there were a few more than I expected, and I did not want to let them go blank or simply duplicate an existing card.

Fixing the Heating at the Lab

It was warm downstairs, and cold upstairs, so I knew the circulator pump was not working. Using my handy voltmeter, I saw that power was going to the motor, so it was not the control circuitry. An online order for new pump, and 2 days later it was waiting for me. Rusty, old, broken on the left, shiny new happy circulator on the right. Nice being able to fix things.

Recent Comments